We understand that the pharmaceutical supply chain is complex and often spans multiple geographies.

At Tower, we work directly with your regulatory and quality teams to protect pharmaceutical products at every stage of the pharma supply chain. Our temperature-controlled shipping solutions support all supply chain processes—from R&D and manufacturing to final distribution.

Our containers are trusted across the pharmaceutical industry, from raw materials and clinical trials to finished pharmaceutical products. Each stage plays a critical role in product safety, stability, and traceability. To remain compliant and avoid costly spoilage, pharmaceutical companies need shipping solutions that deliver real-time temperature control and meet strict quality standards.

As pharma supply chain specialists, we understand how the bullwhip effect impacts inventory, forecasting, and delivery timelines. That’s why we recommend using controlled environments backed by data analytics to improve visibility, reduce risk, and limit product waste.

Stages of the pharmaceutical supply chain

| Raw Materials | Manufacturing | Packaging | Quality Control | Distribution |

| Sourcing APIs, excipients, and packaging materials from approved suppliers—typically coordinated by drug manufacturers and wholesale distributors. | Converting raw materials into tablets, capsules, injections, etc., under Good Manufacturing Practices (GMP). A key part of the supply chain, with compliance critical at every step. | Using approved containers like blister packs, vials, and bottles with labelling and batch codes for traceability. | Ongoing checks during production and packaging to ensure products meet pharmaceutical companies’ standards and regulatory requirements. | Transporting packaged goods to wholesalers, hospitals, or pharmacies. This is where supply chain challenges often arise—especially with temperature-sensitive products. |

| Clinical Research | Regulatory Compliance | Supply Chain Management | Finished Product | Patient Use |

| Generating data on safety and efficacy through trials before a product is approved. This research and development phase is critical for pharmaceutical manufacturers. | Meeting global requirements (e.g. FDA, EMA) through strict processes and documentation. | Handling logistics, inventory management, and transport to reduce costs and streamline operations. Chains in the pharmaceutical supply chain rely on efficiency here. | Delivering approved products to healthcare settings, ready for patient use. | End-use by patients, following prescriptions and dosage guidelines. |

We help pharmaceutical companies address supply chain challenges by offering packaging solutions that support stability, traceability, and compliance—at every stage from research to final delivery.

“Very reliable service, proven reliable solutions that we have 100% faith in and in doing so our clients have the faith in our service.” Neil Black, Client Relationship Manager, Marken

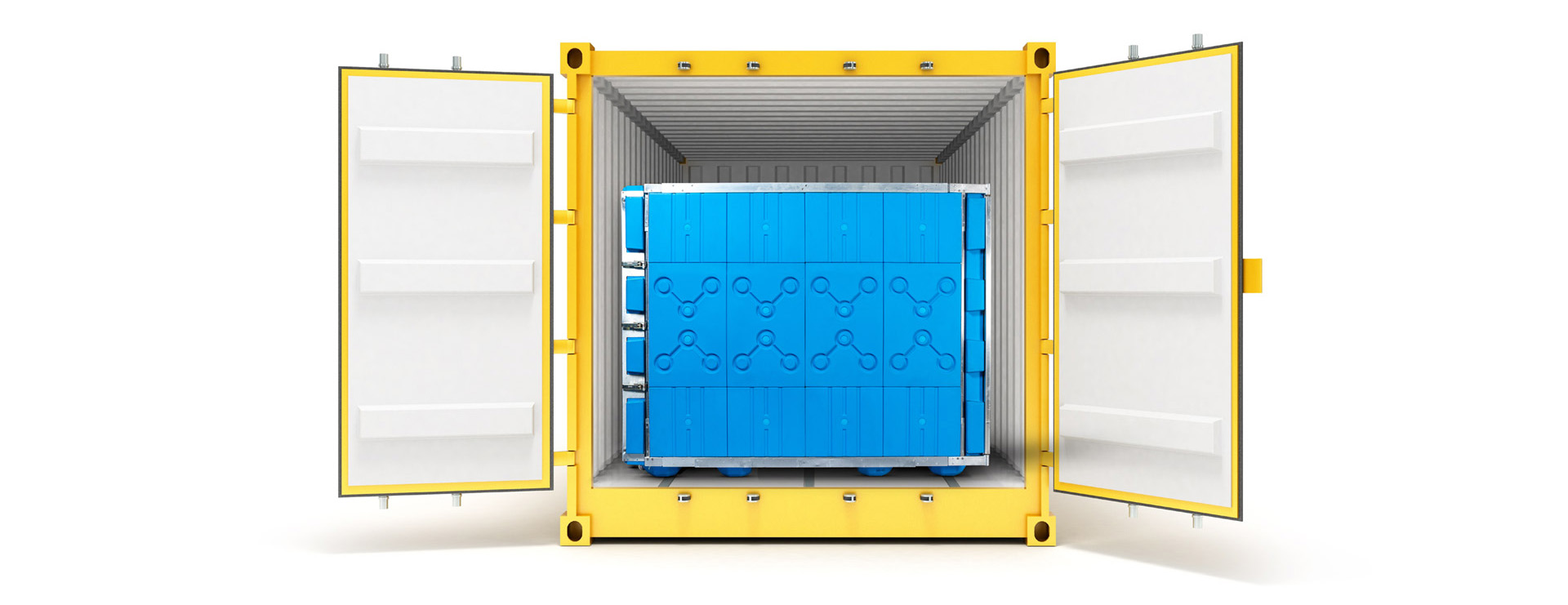

With advanced monitoring and audit trail capabilities enabled through narrow-band IoT cellular technology, customers are provided with complete visibility and peace of mind over their shipments.

- 120+ hour temperature compliance in any environment, anywhere in the world.

- Performance data demonstrates fewer than 0.1% temperature excursions, with early warning of errors through alarms/alerts.

- Reusable temperature-controlled containers that deliver the correct performance for every shipment.

- CFR 21 P11 compliant for full data integrity.

- Online visualisation platform available to monitor shock, tilt, light, motion, altitude, location, and internal & external temperature.

- Tested in triplicate as per summer and winter profile.

Ensuring product integrity for your patients

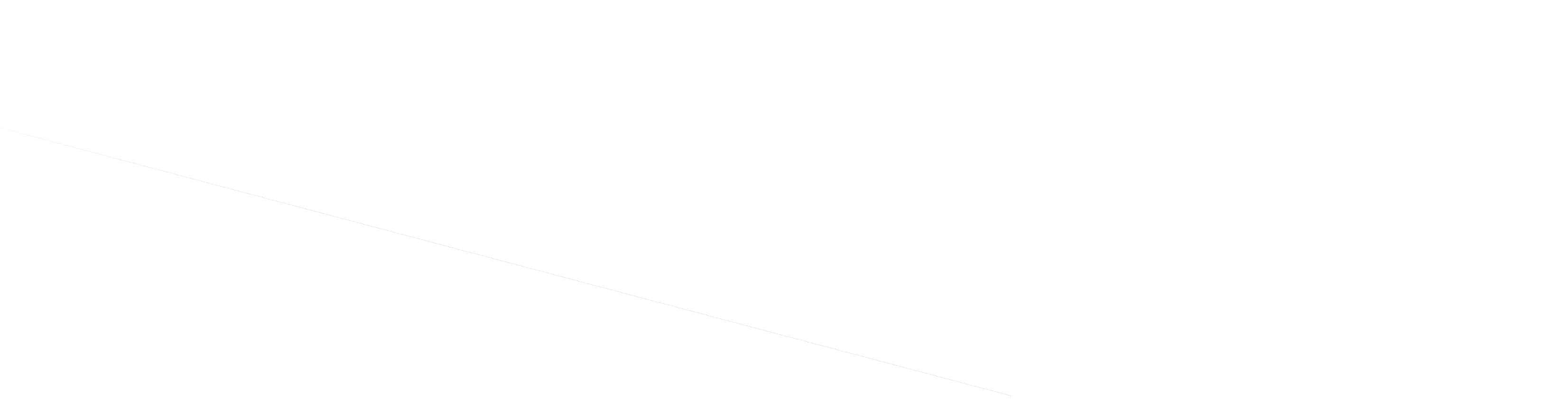

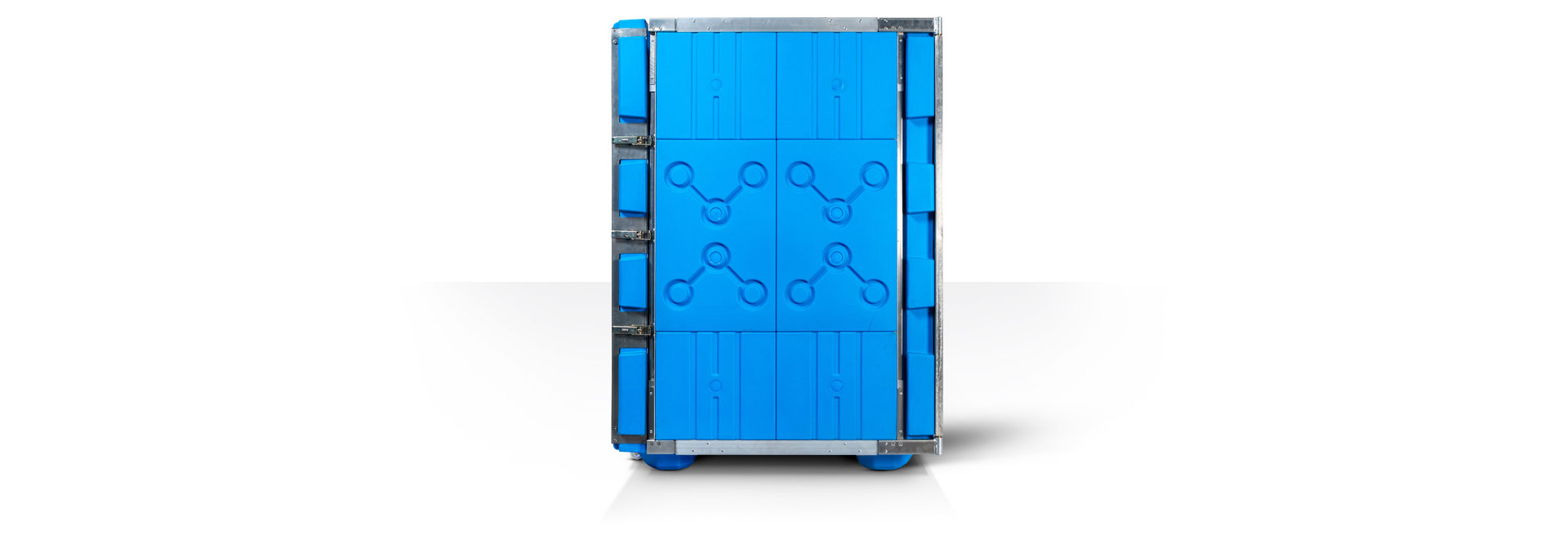

Tower delivers proven physical and temperature protection for pharmaceutical and life science products. Our containers are designed to perform in all supply chains, regardless of the transport type or environment. The innovative internal and external structural design of our containers means pharmaceutical supply chain products will be transported without the need for in-transit manual intervention.

Delivering pharmaceuticals to patients when and how they need them

Data downloaded from over 15,000 shipments has demonstrated fewer than 0.1% temperature excursions on average, a vital indicator in the maintenance of the cold chain. We achieve this by providing a reusable container that delivers the correct performance for every shipment. Our team focuses on delivering a consistent customer outcome whatever the location for the pharmaceutical supply chain.

Efficient and effective results for our global customers

All players in the cold chain have a role to play in sustainability. We see ours as providing a reusable, cost-effective solution that contributes to customers’ circular supply-chain ambition. Customers value our long-term lease containers and supply-chain flexibility.

Find the right cold chain solution for you

Explore our range >Data logger

Data loggers are built into all Tower containers, logging internal temperatures from -95°C (-139°F) up to 50°C (122°F). Users can get text or email notification of temperature excursions, as well as automatic data downloads throughout the transit (in-flight excluded) from loggers within range of the CX Gateway device. The loggers are built to FDA, USP, EU and WHO standards.

Delivering value through customer-focused innovation

Tower incorporates innovation through design to meet the regulatory demands of the pharmaceutical supply chain. Our patented design technology meets the GDP requirements of our customers and exceeds the temperature-control demands of the pharmaceutical industry.

Our expert teams work closely with our customers, realising their requirements and how we can address emerging needs. Tower collaborates with stakeholders to identify challenges across a supply chain and to deliver customer-focused innovation.