Maintaining pharmaceutical integrity through digitalisation

Issue Month: June 2023

The global distribution of temperature-sensitive vaccines brought unprecedented logistical challenges, confirming the need for security and traceability at every step of the pharmaceutical supply chain. The unpredictability of the market, combined with today’s increasingly connected, fast-paced world, means businesses are leaning on their third-party cold storage partners to deploy end-to-end tracking processes and capabilities to ensure product integrity and maintain profits. Data is no longer an ‘added-extra’, but a vital part of cold chain operations. Likewise, packaging which assures product integrity through digital tools is becoming a cornerstone in all stages of supply chain fulfilment and whatever the shipment size.

3 benefits of pharmaceutical digitalisation

- Increased visibility and control

As one of the most regulated industries in the world due to the complexity of regulations regarding production and distribution, the pharmaceutical industry continues to leverage emerging technologies as a means of optimising processes to provide the highest quality and consistency to customers.

Considering the high value of pharmaceutical goods, their perishable nature and susceptibility to temperature changes, every process must be meticulously monitored, from manufacturer to packaging and shipment. A temperature excursion can render an entire batch of products unusable, costing companies time, money, and resources. In addition, faulty batches can cause serious harm to consumers, resulting in lawsuits and reputational damage to companies.

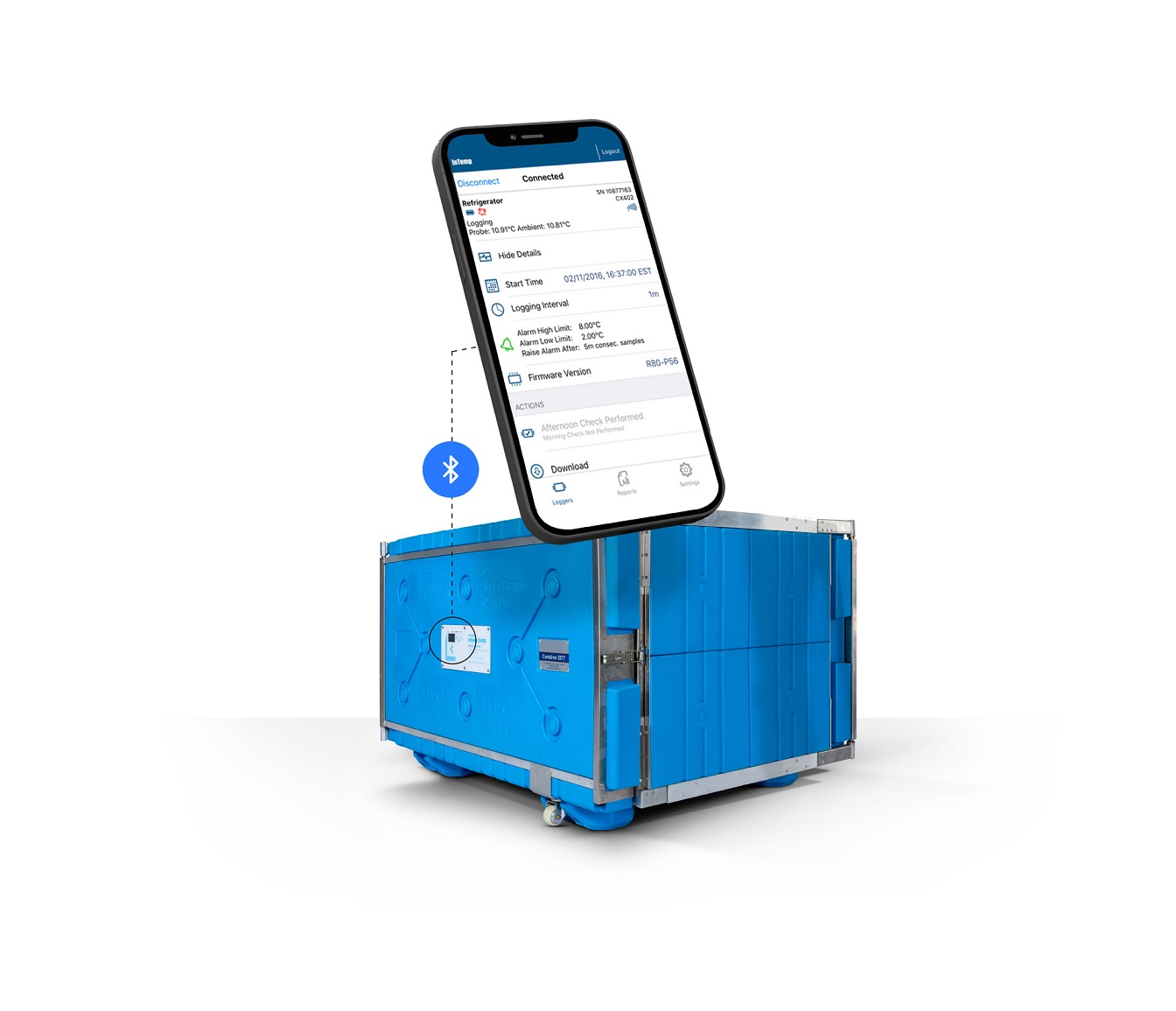

Dataloggers, designed to monitor external and internal temperatures throughout each container’s journey, should be built into containers – a key, aspect in those provided by Tower. Advanced packaging features such as dataloggers, which are integrated into the external body of the container, inform customers of the solutions’ pre-conditioned temperature, prior to goods being placed inside, thus guaranteeing product integrity from the very beginning. Using Bluetooth Low Energy Technology, each logger communicates wirelessly, sending accurate data to the cloud. Users can get a text or email notifications of temperature excursions, as well as automatic data downloads throughout the transit. This data communication allows for accurate compliance checks and on-delivery sign-off, providing complete visibility and transparency to customers.

Tower Cold Chain has also built a cargo temperature simulator, which uses thousands of operational data points to simulate and predict cargo temperatures over a customer’s chosen journey. This predictive technology, combined with the internal and external data loggers, helps customers to understand the potential risks involved in operating a lane before any testing or qualification process have occurred, which helps them to identifying the best packaging solution for use in a lane at any time of year. This impressive monitoring has been created with the aim of predicting and pre-warning customers of any potential temperature excursions well before they happen so that risks are mitigated, product integrity is maximised and product loss is always avoided.

- Cost Reductions

Assurance of product integrity is paramount in cold chain, which is why reliability is a key foundation for logistics providers. But secondly, digital transformation helps to lower per-capita costs in the pharmaceutical industry. In manufacturing plants, digitalisation often involves machine learning, artificial intelligence, and IoT communication. These digitalised processes promote seamless manufacturing operations, automated corrective actions, and better preventive maintenance. As a result, pharmaceutical companies experience fewer errors, downtime, and liabilities, leading to greater cost savings.

- Improved efficiency

All industries are currently dealing with what is being dubbed “The Amazon Effect” – a mindset where consumers have little tolerance for a lack of efficient order processing.

To stay ahead of the curve, pharmaceutical digitisation is the key to improving efficiency and productivity for companies, allowing customers to track orders in real-time; to provide updates on geographical location and shipment progress. The challenge however is finding a cellular GPS solution which is geared towards pharmaceutical shipments and is compatible with airline regulations whilst offering a sustainable battery life. For Tower, we’re actively looking into this sphere, to deliver the newest and smartest solutions to our customers.

Modern technologies such as AI have made it easier than ever to add value to the supply chain. For Tower Cold Chain specifically, advanced automation technologies, such as a digital payload calculator, and a standardised cloud-based control system, provide many opportunities to streamline operations.

With the use of technology and ‘big-data’, Tower are currently building a customer portal which will ultimately provide accurate information at each customer’s fingertips – offering lane and in-transit simulation, 3PL recommendation (providing insight in to which 3PL is most likely to deliver on time) and better visibility into operations, with access to lead times, temperature monitoring, airway bills and global positioning – all from one centralised platform.

Automation methods and predictive technologies centred on historical, accurate data put the building blocks in place to help prove systems are installed correctly from day one, that it operates as expected, and that all processes perform to specification – meaning companies can onboard equipment much quicker, and at less cost.

Leveraging digitalisation for the pharmaceutical supply chain

The baseline requirement for pharmaceutical logistics is that products should arrive on time, undamaged and with no temperature excursions. Advanced technologies are there to enhance this process, so choosing the most appropriate cold chain solution, which is inherently resilient, as well as smart, can make all the difference.

Through the innovative structural design of our passive containers, all products that are shipped with Tower are transported without the need for in-transit manual intervention. Ultimately, the resilience is already there but pharmaceutical digitalisation is helping us to take that process to the next level to maintain a robust, reliable, reusable supply chain.

For more information on pharmaceutical digitalisation at Tower, click here: https://www.towercoldchain.com/cold-chain-technology/